变幅油缸英文

Hydraulic Cylinder with Variable Stroke

Introduction:

The hydraulic cylinder with variable stroke, also known as the variable stroke hydraulic actuator, is a crucial component in various hydraulic systems. It is widely used in industries such as construction, mining, and manufacturing. This article aims to provide a comprehensive overview of the variable stroke hydraulic cylinder, including its working principle, applications, advantages, and maintenance.

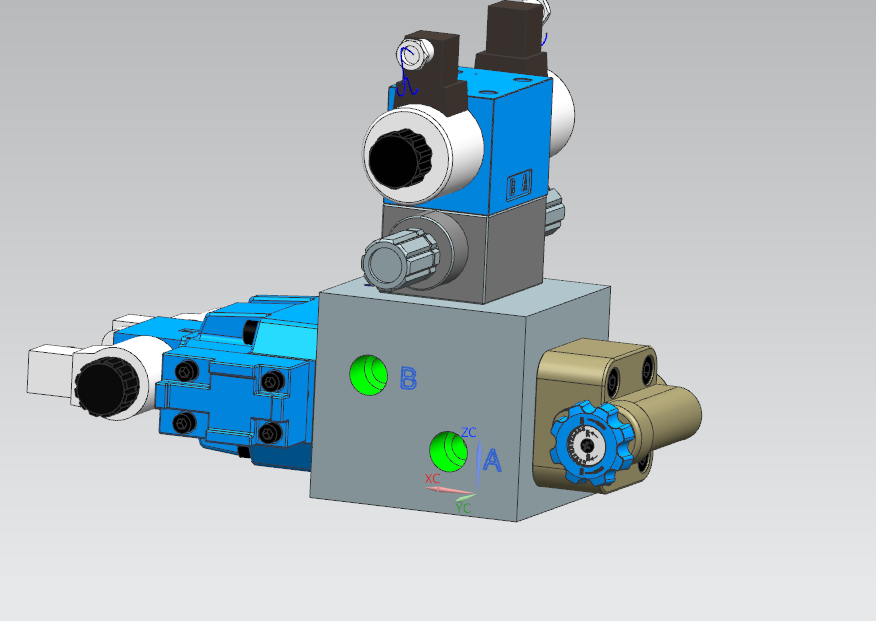

Working Principle:

The variable stroke hydraulic cylinder operates based on the principle of hydraulic pressure. It consists of a piston, cylinder barrel, and hydraulic fluid. When hydraulic fluid is pumped into the cylinder, it exerts pressure on the piston, causing it to move. The stroke length can be adjusted by controlling the amount of hydraulic fluid entering the cylinder. This adjustability allows for precise control of the cylinder's extension and retraction, making it suitable for various applications.

Applications:

The variable stroke hydraulic cylinder finds extensive use in applications where precise control of movement is required. One common application is in construction machinery, such as excavators and cranes. These machines often require adjustable boom lengths, and the variable stroke hydraulic cylinder provides the necessary flexibility. Additionally, it is used in material handling equipment, such as forklifts and conveyor systems, where the stroke length needs to be adjusted based on the load size. The versatility of the variable stroke hydraulic cylinder makes it an essential component in many industrial processes.

Advantages:

The variable stroke hydraulic cylinder offers several advantages over traditional fixed stroke cylinders. Firstly, its adjustability allows for precise control of movement, resulting in improved operational efficiency. This feature is particularly beneficial in applications that require repetitive and accurate positioning. Secondly, the variable stroke cylinder reduces the need for multiple fixed stroke cylinders, simplifying the hydraulic system design and reducing costs. Lastly, it enhances safety by providing better control over the movement of heavy machinery, minimizing the risk of accidents.

Maintenance:

Proper maintenance is crucial to ensure the optimal performance and longevity of the variable stroke hydraulic cylinder. Regular inspection of the cylinder's components, such as the piston, seals, and cylinder barrel, is necessary to identify any signs of wear or damage. Any leaks or malfunctions should be promptly addressed to prevent further damage. Additionally, the hydraulic fluid should be regularly checked and replaced as per the manufacturer's recommendations. Proper lubrication of the cylinder's moving parts is also essential to minimize friction and ensure smooth operation.

Conclusion:

The variable stroke hydraulic cylinder is a vital component in hydraulic systems, offering precise control of movement and improved operational efficiency. Its versatility and adjustability make it suitable for a wide range of applications in various industries. Proper maintenance and care are essential to ensure its optimal performance. By understanding the working principle, applications, advantages, and maintenance of the variable stroke hydraulic cylinder, professionals can make informed decisions regarding its implementation in hydraulic systems.

工良液压技术部整理发布,转发标明出处