小臂油缸英文

Hydraulic Cylinder for Forearm

Introduction:

As an experienced hydraulic expert, I would like to provide a comprehensive overview of the hydraulic cylinder for the forearm. This component plays a crucial role in various hydraulic systems, particularly in heavy machinery and industrial equipment. In this article, we will explore the functions, design, and maintenance of the hydraulic cylinder for the forearm.

Functions:

The hydraulic cylinder for the forearm is responsible for the movement and control of the forearm in hydraulic systems. It converts hydraulic energy into mechanical force, allowing the forearm to perform various tasks such as lifting, pushing, and pulling heavy loads. The cylinder's piston rod extends and retracts, providing the necessary force to move the forearm in a controlled manner. This component is essential for the smooth operation and efficiency of hydraulic systems.

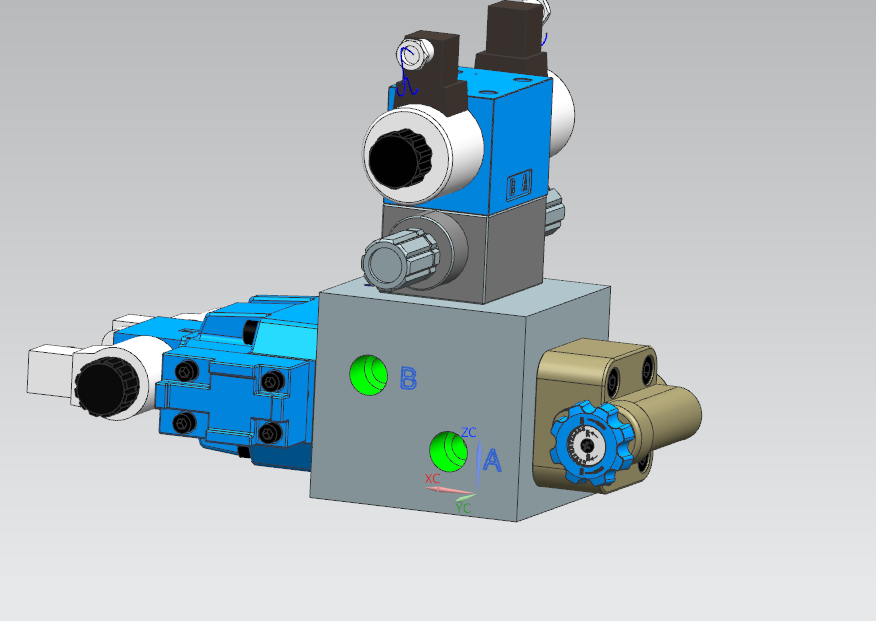

Design:

The design of the hydraulic cylinder for the forearm is based on the principles of fluid mechanics and mechanical engineering. It consists of a cylinder barrel, piston, piston rod, and various seals. The cylinder barrel is a sturdy and durable tube that houses the piston and allows for the movement of hydraulic fluid. The piston is a crucial component that separates the cylinder into two chambers and converts hydraulic pressure into mechanical force. The piston rod connects the piston to the forearm, transmitting the force generated by the hydraulic fluid. Seals ensure the proper functioning of the cylinder by preventing leakage of hydraulic fluid.

Maintenance:

Proper maintenance of the hydraulic cylinder for the forearm is essential to ensure its longevity and optimal performance. Regular inspection and cleaning of the cylinder barrel and piston rod are necessary to remove any dirt or debris that may affect its operation. Lubrication of the seals and moving parts is crucial to reduce friction and prevent premature wear. It is also important to monitor the hydraulic fluid level and quality, as contaminated or low fluid levels can lead to cylinder failure. Any signs of leakage or abnormal operation should be addressed promptly to avoid further damage.

Conclusion:

In conclusion, the hydraulic cylinder for the forearm is a vital component in hydraulic systems, enabling the movement and control of the forearm in heavy machinery and industrial equipment. Its design and maintenance are crucial for the smooth operation and efficiency of hydraulic systems. By understanding its functions, design, and maintenance requirements, operators and maintenance personnel can ensure the optimal performance and longevity of the hydraulic cylinder for the forearm.

工良液压技术部整理发布,转发标明出处