铲斗油缸英文

Introduction

The bucket cylinder, also known as the shovel cylinder or bucket oil cylinder, is an essential component in hydraulic systems. It plays a crucial role in various heavy machinery, such as excavators, loaders, and bulldozers. In this article, we will explore the bucket cylinder in detail, including its functions, structure, and working principles.

Function of the Bucket Cylinder

The bucket cylinder is primarily responsible for controlling the movement of the bucket or shovel in heavy machinery. It enables the machine to perform tasks such as digging, lifting, and dumping materials. By extending and retracting the cylinder, operators can control the position and angle of the bucket, allowing for efficient and precise operations.

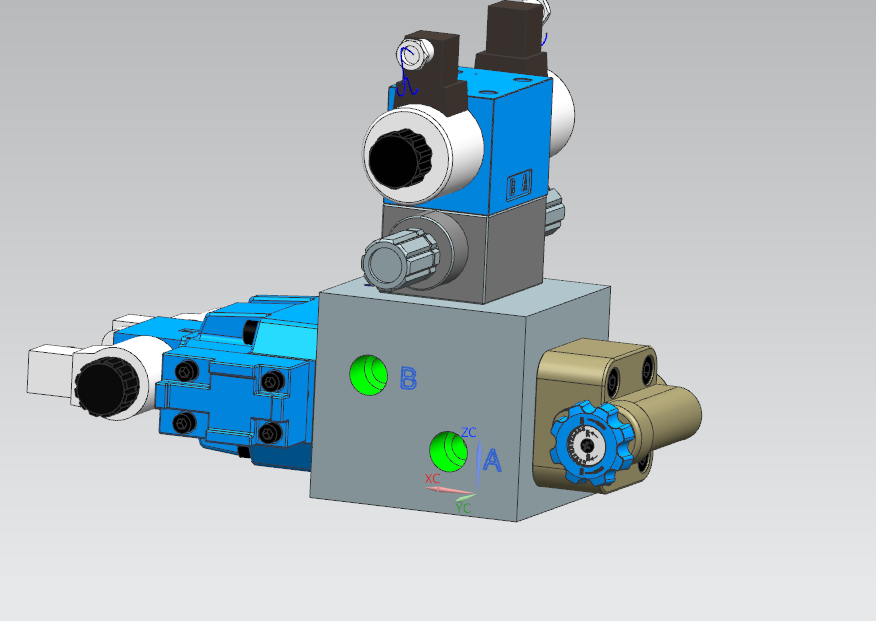

Structure of the Bucket Cylinder

The bucket cylinder consists of several key components, including the cylinder barrel, piston, piston rod, and end caps. The cylinder barrel is a cylindrical tube that houses the piston and allows for the movement of hydraulic fluid. The piston, connected to the piston rod, divides the cylinder barrel into two chambers: the rod side and the head side. The end caps seal the cylinder barrel and prevent leakage of hydraulic fluid.

Working Principles of the Bucket Cylinder

The bucket cylinder operates based on the principles of hydraulic power. When hydraulic fluid is supplied to the rod side of the cylinder, it pushes the piston and extends the cylinder. Conversely, when hydraulic fluid is supplied to the head side, it retracts the cylinder. This extension and retraction of the cylinder control the movement of the bucket, allowing for various operations.

Maintenance and Troubleshooting

Proper maintenance of the bucket cylinder is crucial to ensure its optimal performance and longevity. Regular inspection of the cylinder for any signs of wear, leakage, or damage is essential. Additionally, maintaining the appropriate hydraulic fluid level and ensuring its cleanliness is vital for the smooth operation of the cylinder.

In case of any issues with the bucket cylinder, troubleshooting can help identify and resolve the problem. Common problems include cylinder drift, slow operation, and leakage. Cylinder drift can be caused by worn-out seals or internal leakage. Slow operation may be due to insufficient hydraulic fluid or a faulty control valve. Leakage can occur due to damaged seals or loose connections. Identifying the root cause of the problem and taking appropriate measures, such as replacing seals or tightening connections, can help resolve these issues.

Conclusion

The bucket cylinder, or shovel cylinder, is a critical component in hydraulic systems used in heavy machinery. Its primary function is to control the movement of the bucket, enabling various operations such as digging, lifting, and dumping materials. Understanding the structure and working principles of the bucket cylinder is essential for operators and maintenance personnel to ensure its optimal performance.

Remember to regularly inspect and maintain the bucket cylinder to prevent any potential issues. By following proper maintenance procedures and troubleshooting techniques, you can ensure the smooth operation of the bucket cylinder and extend its lifespan.

工良液压技术部整理发布,转载请标明出处